CNC milling and turning

Milling is a permanent element of machining all kinds of planes, channels, grooves, shaped surfaces or serrations and is one of the most frequently used and most efficient methods of machining. It gives the desired shape to objects made of metal, wood, plastic or other machinable materials using a multi-blade knife.

Milling is a permanent element of machining all kinds of planes, channels, grooves, shaped surfaces or serrations and is one of the most frequently used and most efficient methods of machining. It gives the desired shape to objects made of metal, wood, plastic or other machinable materials using a multi-blade knife.

There are several milling methods. They can be divided into cylindrical and shaped milling techniques. Another division is this due to the way the blades move.

Advantages of CNC milling:

- streamlining the production process thanks to automation,

- wide range of compatible materials,

- high accuracy and precision,

- maximization of production thanks to solid, long-lived machines,

- fast production for medium and large quantities of products.

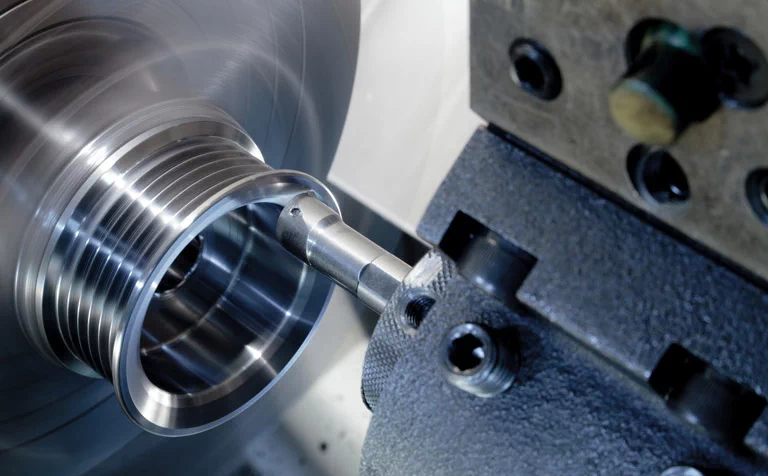

Turning

Turning is a specific type of machining involving the removal of excess material, usually in the form of chips. It is used when machining external and internal surfaces of workpieces in the shape of a solid of revolution. In order to obtain the desired shape and size, individual layers of material are separated using a turning tool.

CNC lathes are most often used, significantly streamlining the work and guaranteeing high precision. Thanks to the use of modern solutions, the entire process is computerized, and most tasks are performed using a computer-controlled device and dedicated software.